Milling Cutter>>>Tools

Brand Name HYCNC

Certification None

Origin CN(Origin)

Type Flat End Mills

Overall Length 60-120mm

Model Number Milling Cutter

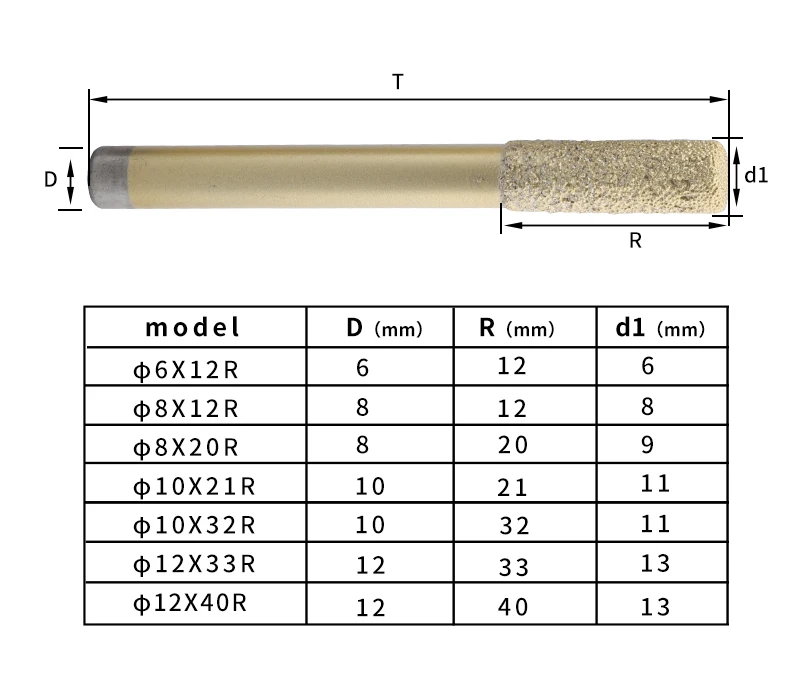

Diameter 6mm 8mm 10mm 12mm

Material Tungsten Cobalt Alloy

Degree R2.0

name Flat bottom slotted straight knife

suitable marble bluestone sandstone

type diamond drill bit

keywords masonry drill bit

shape Flat slot

usage CNC machine tools

handle Straight handle

Features Sharp cutting edge, not easy to break

Cutting Edge Length

Random delivery in multiple colors

Random delivery in multiple colors

1pc flat-bottom slotted straight-knife welded sintered stone engraving flat-bit drill for marble granite, used for CNC machine tool engraving tools

Weld stone is sharp and wear-resistantOptimized steel; diamond grain; sharp cut; high wear resistance and durabilityProduct name: Flat-bottom slotted welding stone carving knifeProduct material: tungsten steel (hard alloy)Product handle diameter: 6/8/10 / 12mmProduct blade length: 12-40mmTotal product length: 60/90/120mmBlade width: 6/8/10/12mmBlade shape: flat bottom/slotApplicable materials: marble, bluestone, sandstone, granite and other stone carving operationsFeatures:The tool head is made of emery material. Sharp, not easy to wear. It is very durable.The blade is made of tungsten steel, and the blade adopts advanced emery melting technology. High hardness, wear resistance, heat resistance, sharp wear resistance, no deformation of the cutter head, high processing efficiency.01High-quality emery cutter head with uniform emery particles, sharp cutting, not easy to carry, no knife marks, strong and constant tool02 Anti-oxidation coating-the cutter head is coated with high temperature resistant coating, which is anti-oxidation and prolongs the tool life03 Tungsten steel handle-the knife body is made of tungsten steel, sturdy and durable, and the bevel design is firm

Applicable processing materials

Suitable for marble, bluestone, sandstone and other stones Cutting and engraving

Machine reference value

The recommended speed is 20,000 rpmZ-direction feed speed 100-300When cutting, the cutting is layered, and the cutting depth is 0.5-5MM at a time. The processing speed is between 1000 and 3000. Coolant or water cooling must be turned on to prevent burning.The above numerical control machine parameters are for reference only, please adjust according to the actual situation.E.g:1. If you want to increase the speed rate, the granite can be cut at a depth of 5mm, but the damage to the knife is relatively large.2. But if you are engraving soft stone such as marble, bluestone, sandstone, and the height of the knife allows, you can directly cut to the end (provided that the cutting speed is appropriate and sufficient cooling water to ensure that the knife is not burned) do not stratify. That is, if the knife height is 10MM, the depth of 10MM can be cut directly.3. Proper cutting speed must be set. Obviously, the cutting speed of 1cm deep under one cut cannot be the same as that of 1mm deep under one cut. Otherwise, moving the knife too fast under 10mm depth will cause excessive pressure and break the handle.4. The coolant or water cooling must be turned on when using.

Widely applicable

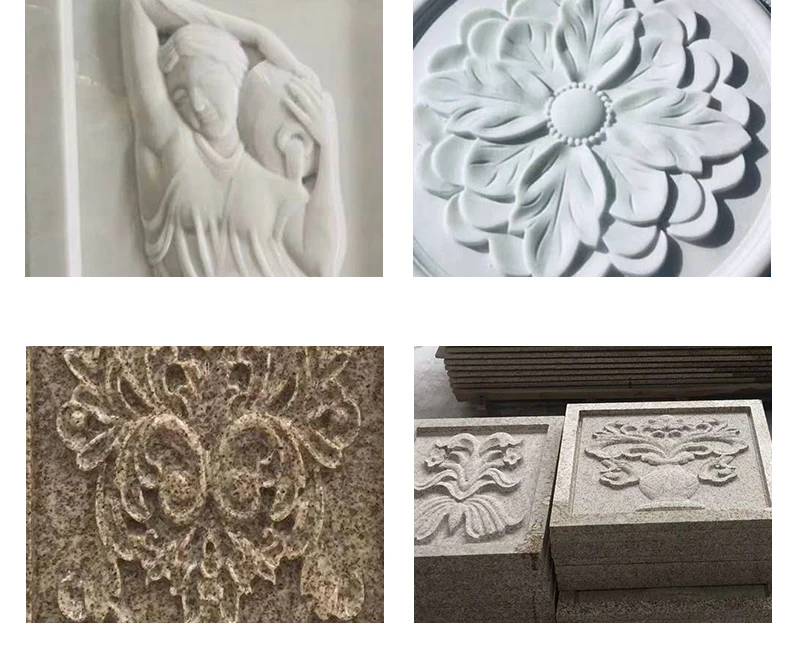

Examples of stone carving

Diamond cutter head

The two layers of sand on the cutter head are sharp, not easy to wear, wear-resistant and durable

"Smelting Emery" Process

Temperature-resistant and wear-resistant tools are tough and firm and have a long service life

◆About tool handle diameter

The choice of the diameter of the tool holder is mainly to choose a reasonable tool body strength to prevent the tool from breaking. Generally speaking, 8MM shank diameter is preferred for reliefs within 2 cm, and 10MM shank diameter is preferred for reliefs above 2 cm. The engraving machine has excellent performance and customers who run high-speed can choose a 12MM tool holder to meet the high-speed requirements.

◆About the tool tip size

In the case of meeting the requirements of engraving accuracy, try to choose a model with a larger tip. The larger the tip, the longer the life. For example, if the 6MM tool tip can meet the requirements of engraving accuracy for large-size reliefs, try not to choose a 3MM or 4MM tool tip.

◆About blade length

Depending on the flatness of the stone and the set carving depth, you should choose a blade length with margin to prevent accidental sharpening of the knife handle. For example, if the engraving depth is 26MM, the blade length is 30MM. If the engraving depth is 15MM, the blade length is 20MM.

Company information and contact information

Jinan Hongyang CNC Machinery Co., Ltd. was established in 2015. There are more than 100 employees, and the inventory area is 10,000 square meters. It is mainly engaged in engraving machine parts, including spindle motor, frequency converter, stepper motor, drive, hybrid servo motor, servo motor, Richauto dsp series controller, weihong or nc studio controller, spindle cooling water pump, lubricating oil pump, tool sensor, Limit sensors, water-cooled vacuum pumps, air-cooled vacuum pumps, power supplies, transformers, gear boxes, racks, rails, sliders or blocks, ISO30 tool clips, cable chains, spindle dust covers, vacuum cleaners and other engraving machine accessories, welcome your For inquiries.Contact information WeChat whatsapp mobile 8615650000988lily @ hycncrouter. com

No comments:

Post a Comment